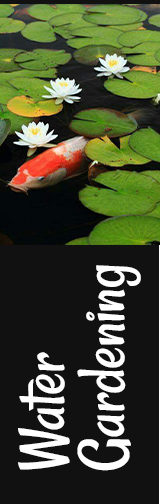

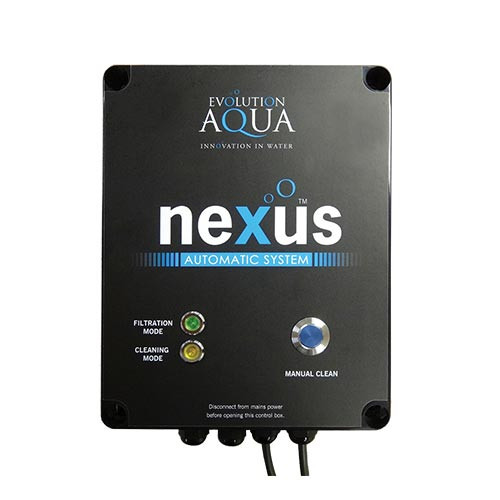

The new design of the Eazy enables the Nexus to capture solids more effectively than before. K1 Micro is used inside the re-designed Eazy helping to deliver improved capture of fine particles, delivering unrivalled mechanical filtration.

Improved Flow

The new Eazy features an improved pattern of slots in the stainless steel body which makes the filter more efficient. Water can pass through the Eazy through all sides and from below, much more effectively than before. This feature combined with the use of K1 Micro makes for improved flow rates through the entire mechanical filter stage.

Dramatically Improved Clarity

The Nexus 320 and 220 filter systems use two types of filter media to deliver optimum levels of clarity in your pond. K1 Micro is used in the Eazy to improve mechanical filtration while the tried and tested K1 Media is used in the moving bed outer chamber, delivering the biological filtration.

Easy To Clean And Maintain

A key feature of all Nexus filtration systems is the sheer ease of maintenance. This still remains the case with the new Nexus 220 and 320 systems. The Eazy is simply cleaned by using a combination of the cleaning pipe, air valves and ball valves fitted to the Nexus, meaning you don’t need to get your hands dirty. The clear lid fitted to the Eazy also makes it easy to visual inspect the K1 Micro media.

Better Solids Handling

Inside the centre mechanical stage of the Nexus, there is a much larger area for solid waste to be captured and to settle. This area can then be cleaned even easier than before ensuring the filter does not clog up with unnecessary amounts of waste.

Removable Eazy

All Eazy filters used in the Nexus 320 / 220 series can be removed if needed with the K1 Micro in place. This added feature is ideal when undertaking further maintenance.

Flow Rates

One of the factors that can have a significant influence on the general parameters of our ponds is turn over rate. This is the time that it takes for the total volume of the pond to pass through the filter system once. We recommend that for ideal performance a turn over rate of every 2 to 3 hours is found to be best.

Have a question? Chat with us

Have a question? Chat with us See something odd? Give feedback here

See something odd? Give feedback here